Biomechanics Research

Specialized equipment can also be used to examine the mechanical strength of musculoskeletal systems and implants, investigate the failure mechanism of bone-implant constructs, and study patients’ motion characteristics. The lab is also furnished with a powerful computer and sophisticated software for computer simulation and analysis of complex bone-implant constructs. Our computer generates patient-specific 3D geometric models based on CT/MRI images, performs virtual orthopedic surgery based on the patient's computer model, analyzes the construct strength and evaluates the potential for long-term implant survival.

MTS 858 Mini-Bionix Biaxial Load Frame

MTS, Inc.

Compression/tension capability: 25 KN/5.5 Kip

Torsion capability: 200 N-m/1770 in-lbf

This biaxial MTS material testing system is for biomechanical testing of tissues, implants, prosthetics and biologically inspired materials. It designed for both static and dynamic test that combines tension-compression and torsion loads. This machine is ideal for fatigue testing and load to failure testing. Utilized with other equipment such as motion capture system, strain gage, or acoustic emission systems, we can replicate biological forces and displacements in lab conditions and investigate the material properties of bone/soft tissue/implant and failure mechanisms of various orthopedic implant-bone constructs.

3D investigator Motion Capture System

NDI, Inc.

3D RMS accuracy: 0.45 mm

3D resolution: 0.01 mm

Sensing volume: 4 m x 3 m x 7 m

This portable motion capture system can simultaneously monitor 512 markers with high accuracy at rates up to 4kHz. It is a powerful technique for measuring human movement and investigating the relative motion among bones or bone fragments. Current applications include investigating the fatigue failure mechanism of bone fracture fixation, tracking relative motion among vertebra, and patient gait analysis.

VFlash 3D Printer

3D Systems

Max Build Size: 9" x 6 3/4" x 8" (228 x 171 x 203 mm)

VFlash 3D Printer can convert a 3D computer model of a patient's bones/blood vessels/nerves/muscles to a physical model that can be hand held. The computer model can be generated based on a patient's CT or MRI scans. Through the physical model physicians can better understand the extent of tissue damage and can devise the most appropriate surgical plan before going into the OR. The physical model has been used in many clinical areas such as orthopedics, trauma, neurosurgery, craniofacial, heart and vascular, and plastic surgery.

microSAMOS Acoustic Emission (AE) System and Portable AE System

Physical Acoustics Corp.

8 AE sensors (can be expanded to 24 sensors)

Simultaneous AE features and waveforms

Acoustic Emission (AE) is a non-destructive, real-time technique to monitor the initiation and propagation of fatigue-induced microcracks in bone-implant constructs. Currently we use the microSAMOS system to detect the microcrack (damage) progress in total hip arthroplasties and humeral fracture fixed with locking plate. We plan to use the portable AE system to monitor patients' bone fractures. Potential projects include monitoring the friction of cartilage in patients who need total joint replacement and the wear of implants in patients who already have undergone joint replacement.

Isomet 1000 Precision Saw

Buehler, Inc.

975 RPM

0.015” thick diamond blade

The Isomet 1000 Precision Saw can cut cadaveric bones and metallic/plastic implants. It is mainly used to create cross sections of bones and implants, and investigate their failure mechanisms due to fatigue or impact loading.

Model 634.12F-24 Axial Extensometer

MTS, Inc.

Gage Length: 25 mm +/- 0.050 mm

Maximum Travel: 12.50 to -2.50 mm

Axial Extensometer is accurate measuring equipment ideal for critical linear displacement measurements. Applications include measuring subsidence of arthroplasties and relative movement between fractured bones.

Computer and Software

HP xw8600 Workstation (QuadCore, 10G memory)

ABAQUS: finite element analysis, stress/strain/motion analysis

Unigraphics NX6: computer aided design

Mimics: medical image 3D reconstruction

Rhinoceros: computer aided design

This powerful equipment and sophisticated software applications enable us to evaluate a patient’s clinical condition, perform virtual surgery and design orthopedic implants. Most important, they can help us evaluate the performance of various bone-implant constructs based on biomechanical disciplines and to estimate the surgery outcome. Besides traditional biomechanical research, computer simulation technique has excellent potential in clinical practice to assist physicians in choosing the right implant and procedure for specific patients in complex and complicated cases. We will collaborate with orthopedic physicians to provide better service to Inova patients.

Arthroscopic Surgical Tower

ConMed Linvatec, Inc.

This is full-function arthroscopic surgical equipment is designed to train physicians and residents in the Washington, D.C., area on minimal invasively joint examinations and surgical procedures. Targeted treatment focuses on torn floating cartilage, torn surface cartilage, trimming damaged cartilage, tendon reconstruction and muscle reconstruction.

Top of page

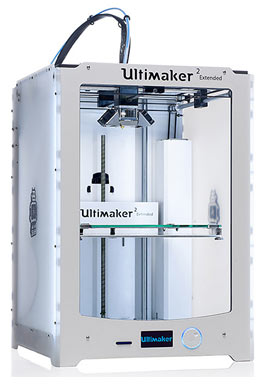

3D Printers

3D Printers Envision One cDLM printer can print flexible to rigid, standard to biocompatible materials. It is perfect for surgical guides or medical supplies with biosafety requirements. It has a maximum build area of 180 x 101 x 175 mm (7.09 x 3.98 x 6.89 in.).

Envision One cDLM printer can print flexible to rigid, standard to biocompatible materials. It is perfect for surgical guides or medical supplies with biosafety requirements. It has a maximum build area of 180 x 101 x 175 mm (7.09 x 3.98 x 6.89 in.). Stratasys uPrint SE Plus is a single color printer. ABS is a strong material and printed parts can endure mechanical loads. uPrint SE Plus has a maximum build area of 203 x 203 x 152 mm (8 x 8 x 6 in.).

Stratasys uPrint SE Plus is a single color printer. ABS is a strong material and printed parts can endure mechanical loads. uPrint SE Plus has a maximum build area of 203 x 203 x 152 mm (8 x 8 x 6 in.). XR equipment

XR equipment